https://www.keppelseghersbelgium.com/wp-content/uploads/2024/02/KSBE_00983.jpg

1000

1000

KSBE_admin

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/04/Keppel-Seghers1.png

KSBE_admin2024-02-28 16:18:042025-01-23 10:44:24Sands of Change: Qatar’s Journey in Sustainable Waste Management

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/02/KSBE_00983.jpg

1000

1000

KSBE_admin

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/04/Keppel-Seghers1.png

KSBE_admin2024-02-28 16:18:042025-01-23 10:44:24Sands of Change: Qatar’s Journey in Sustainable Waste ManagementPoland’s clean energy milestone: The success story of the Bialystok Waste-to-Energy plant

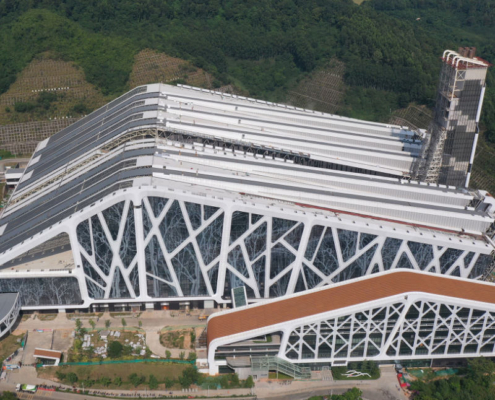

Location: Bialystok, Poland

Category: Waste-to-Energy and Recycling Plants

Contract type: Engineering, Procurement and Contracting (EPC)

Scope of contract: Contract type: Scope of the contract includes providing Engineering, Procurement, and Construction (EPC) services from waste intake chute to exhaust stack, inclusive of bottom ash treatment and maturation. This excludes civil works, the steam condensate circuit, and building services.

Number of Production Lines: The facility features a single production line equipped with a SIGMATRIX air-cooled combustion grate, accompanied by a vertical boiler and a conditioned dry flue gas treatment system. The plant processes 372 tons of municipal solid waste daily, generating 8.6 MW of electricity in the summer. During the winter, it produces 6 MW of electricity and 17.5 MW of thermal energy.

Construction period: 2013 – 2015

Poland’s commitment to EU environmental goals

Since its accession to the European Union (EU) in 2004, Poland has been dedicated to fulfilling the requirements of the EU Landfill Directive, with a particular focus on minimising the landfilling of biodegradable waste. This commitment underscores the nation’s efforts to adopt sustainable waste management practices and reduce environmental impact. In alignment with these objectives, Keppel Seghers, was selected as part of a consortium to implement a pioneering Waste-to-Energy combined heat and power project in Bialystok, Poland. This initiative signifies a substantial step forward in Poland’s journey toward achieving its environmental ambitions.

Innovative Waste-to-Energy solutions by Keppel Seghers

Bringing to the table its vast experience from over 100 WtE projects worldwide, Keppel Seghers contributed its cutting-edge proprietary technology to the Bialystok project. The deployment of Keppel Seghers’ air-cooled grate and vertical boiler systems is pivotal in ensuring efficient energy recovery and operational dependability. These technologies are engineered to maximise the conversion of waste into energy, thereby contributing to environmental sustainability and operational excellence. Keppel Seghers’ role in providing these innovative solutions underpins the project’s goal of transforming waste management and energy production in Bialystok.

20 months

building period

1

production line

120K

tonnes of waste per year

Impact and output of the Bialystok Waste-to-Energy plant

Upon completion, the Bialystok plant is set to process roughly 120,000 tons of waste annually, dramatically reducing the volume of municipal waste destined for the Hryniewicze landfill site from over 90% to around 12%. During the summer months, the facility is expected to generate approximately 8.6 MW of electricity. In the winter, it will adapt to produce 17.5 MW of thermal energy for Bialystok’s district heating network, alongside 6 MW of electricity for the grid. This dual functionality not only showcases the plant’s versatility in energy production but also its significant contribution to reducing waste and supplying energy to the community.

A showcase of strong collaboration and technological excellence

The Bialystok project is a testament to the power of collaboration and technological innovation. Partnering with local construction firm Budimex, the consortium leveraged each partner’s core competencies to navigate challenges, including a compressed 20-month construction timeline and delays in the permitting phase. Keppel Seghers’ comprehensive delivery of the electromechanical components—from the feeding hopper to the stack—played a crucial role in meeting the plant’s performance guarantees.

Currently in 2024, after seven years of operation, the plant’s SIGMATRIX combustion grate has not required a single tile replacement, underscoring the project’s success and the facility’s standing as one of Poland’s most efficient Waste-to-Energy plants to date.

Highlights

-

The project was completed within an impressively short timeframe, with only 20 months elapsing between the start of erection and the completion of erection.

-

In the third and fourth years of operation, the plant achieved an availability of over 8,100 hours, indicating high reliability and operational efficiency.

-

After seven years of continuous operation, there has been zero replacement of tiles on the combustion grate, showcasing the durability and quality of the technology used.